Formech Technical Newsletter - Male and Female Tooling

Formech Technical Newsletter - Male and Female Tooling

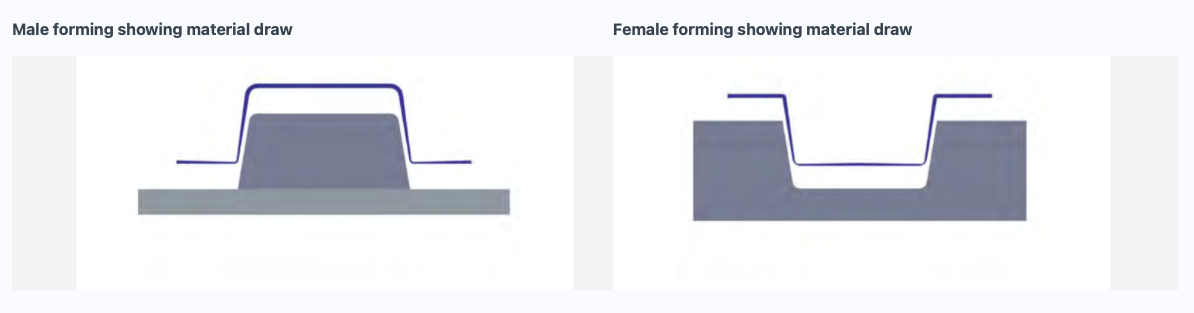

Sometimes the concept of male and female tooling / moulds can be a bit confusing to those that are new to the vacuum forming process. The following descriptions cover the main differences between the different types of tooling

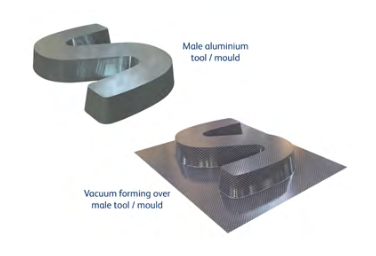

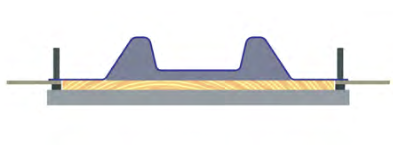

Male tool / mould

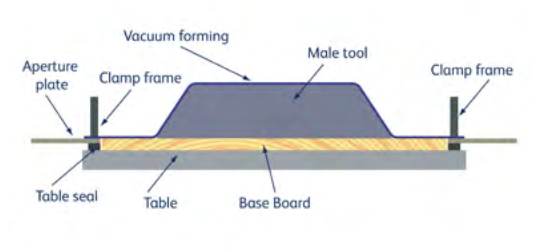

Definition: This is a positive tool that when formed produces a forming that is above the clamping of the clamped sheet.

Why use a male tool? The material flow and wall thickness of the formed part are different from a female tool. In addition, the tooling costs are usually less expensive than those for a female tool.

What type of resin to use

The visible surface of the formed part is usually the top surface and therefore the thickness of the plastic sheet tends to hide some of the imperfections on the tool surface, producing a more attractive surface finish.

Some details will be difficult to achieve on a female tool e.g. deep cavities with a thick base and corners (unless a plug assist is used).

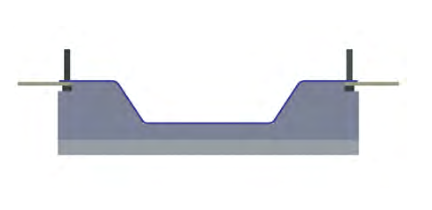

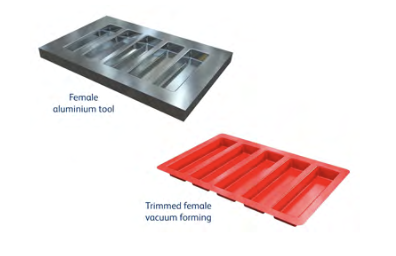

Female tool / mould

Definition: This is a tool that when formed produces a forming that is below the clamping of the clamped sheet. The tool does not project above the clamping of the clamped sheet.

Why use a male tool? The material flow and wall thickness of the formed part are different compared to a female tool.

What type of resin to use

If sharp details are required then the underside of a female forming could be used as the visible surface. Some details are not possible as a male tool. Shrinkage – the vacuum forming will shrink away from the side of the tool. Close spacing of tooling result in cost savings in material. You don’t have to consider any outer vertical walls as on a male tool and the possibility of webbing is often reduced.

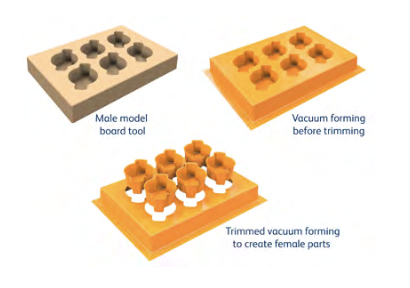

Male tool with female cavities

Definition: This is essentially a male tool which can be used to create female vacuum formings.

Why use a tool like this? You may want to create female parts without having to make conventional female tools and you don’t mind the extra material cost per cycle.

This method of using a male tool to produce female formings can be used for reel feed material where a female or negative vacuum forming (position below the clamp) would cause problems when trying to advance the formed sheet through the machine, unless your machine features a negative gate.

Formech Technical Newsletter compiled by: Martin Smith, Senior Technical Support Manager, [email protected]

>>> Download PDF here